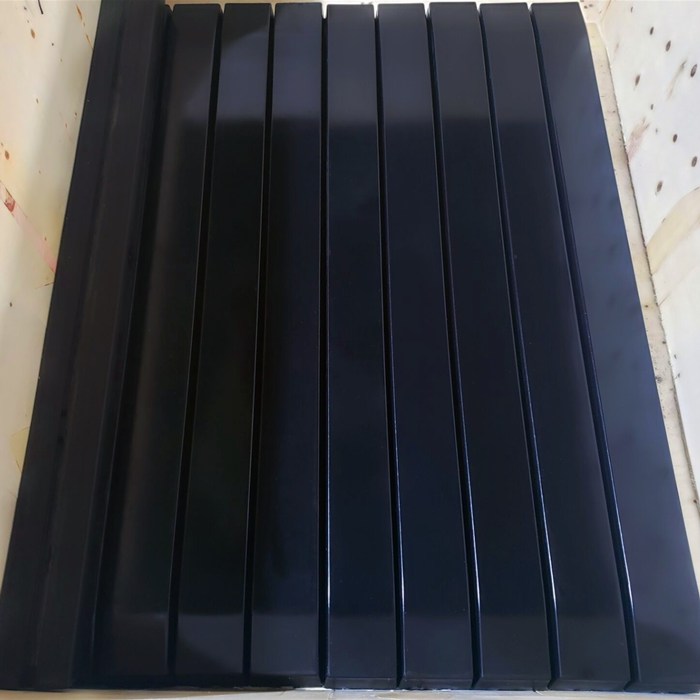

Conveyor Impact Bar structure:

The Conveyor Impact Bar is made of buffer tape (commonly known as blackboard) and ultra-high molecular weight polyethylene (UHMWPE) by hot vulcanization process.

The Conveyor Impact Bar is made of metal skeleton and rubber by thermal vulcanization.Generally, the metal skeleton is made of c-section steel and aluminum alloy. The skeleton is mainly used to connect the support of the buffer press.We are equipped with anti-loose bolts to ensure that the buffer strip is firmly fixed to the buffer support and can withstand impact for a long time without loosening.

Conveyor Impact Bar technical parameters:

Surface material: UHMW-PE (Ultra High Molecular Weight Polyethylene) | ||

Surface color | Black / white / red / blue / green | |

Molecular weight | 5.5-7.2 million | |

project | Test Methods | standard |

tensile strength | ASTM D638 (test rate 50mm/min) | More than 250kgf/cm2 |

Impact strength | ASTM D256 (test rate 50mm/min) | More than 100kgf/cm2 |

Wear resistance | ASTM D4060-01 (1000g, cs-17, 1000 rpm) | Less than 6mg |

Coefficient of friction | ASTM D1894-01 (complex for rubber belt) | Less than 0.1 |

Peel strength | ASTM D903 (UHMW-PE and rubber) | 50kgf/25mm |

Rubber part (buffer body): NR | ||

Rubber color | Black | |

project | Test Methods | standard |

tensile strength | CNS 3553 K6344 | More than 220kgf/cm2 |

Elongation | CNS 3553 K6344 | More than 400% |

Peel strength | ASTM D903 (rubber and metal parts) | 60kgf/25mm |

hardness | ASTM D256 | 55±5(SHORE A) |